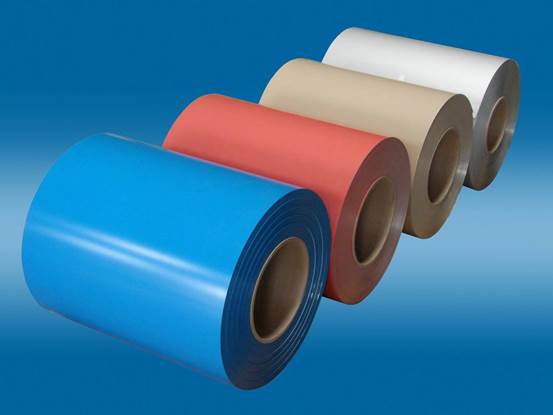

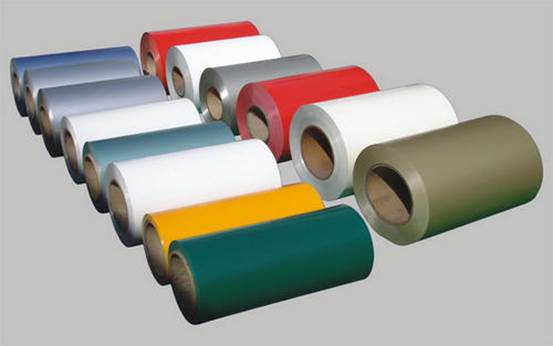

The aluminum coil is a metal product for the flying shear after the casting mill has been subjected to calendering and drawing. Aluminum coils are widely used in electronics, packaging, construction, machinery, etc. And the production process has caught up with developed countries. According to the different metal elements contained in aluminum coils, aluminum coils can be divided into 9 categories. , that is, divided into 9 series.We have PE coated aluminum coils,HDP,FEVE and PVDF coated aluminum coils.

PE color coated aluminum coils are processed with precise roll coating techniques and baked polyester coatings. Its color is smooth and a wide variety of colors to choose from.

The polyester coating formed by multiple baking of the surface of the aluminum plate can form a solid continuous film which is firmly adhered, and is an anti-UV additional wire coating which has the characteristics of protective decoration. The polyester resin is a monomer having an ester bond-containing polymer in the main chain, and an alkyd resin and an ultraviolet absorber are added. The polyester coating protects objects exposed to the atmosphere from exposure to ultraviolet radiation, wind, rain, frost and snow.

The fluorocarbon coating is a coating of PVDF resin mainly referring to a vinylidene fluoride homopolymer or a copolymer of vinylidene fluoride and other small amount of fluorine-containing vinyl monomer. The chemical structure of the fluoric acid base is combined by a fluorine/carbon bond. This chemical structural stability and firmness make the physical properties of fluorocarbon coatings different from conventional coatings. In addition to the abrasion resistance in terms of mechanical properties, impact resistance has excellent performance, especially in harsh weather and environment, showing long-lasting resistance to fading and UV. After the high temperature barbecue is formed into a film, the molecular structure in the coating is tight and has excellent weather resistance. Fluorocarbon coatings can be classified into conventional fluorocarbon and nano fluorocarbon coatings according to the surface film formation structure. The highest priority of PVDF coated aluminum coils is the selection of high-grade aluminum composite panels and their composite products, which are widely used in airports, convention centers, management centers,roof, star-rated hotels and other buildings。