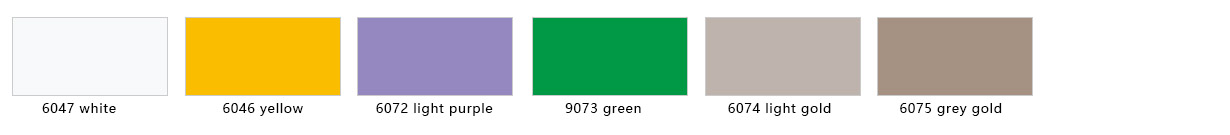

Color card of the product

FEVE Coating

1. FEVE aluminum composite panel has high quality polyurethane as the primary coat and mid-high baked fluororesin as the surface coating. It has a 10-15 year weather resistance. Its colors are more brilliant and glossier than the PVDF fluorocarbon coating. The color's diversification and uniqueness make it unparalleled by other painting systems. It's especially suitable for decorations and exhibitions of commercial chains, auto 4S stores, and gas stations where the color effects are required.

| Raw Material | Product Specifications | ||||||||

|

|

Product Data Sheet

Pivot ACM( architecture )

| Panel Thickness | Standard | Unit | 3mm | 4mm | 6mm |

| Thickness of Aluminium | DIN 1784 | mm | 0.5 | 0.5 | 0.5 |

| Aluminum thickness deviation | DIN 1784 | mm | ±0.01 | ±0.01 | ±0.01 |

| Weight | Kg/m2 | 4.65 | 5.63 | 7.42 | |

| Tolerance in length | DIN 16927 / ISO 11833-1 | mm | - 1 / +3 | - 1/ +3 | - 1/ +3 |

| Tolerance in width | DIN 16927 / ISO 11833-1 | mm | - 1 / +1.5 | - 1 / +1.5 | - 1 / +1.5 |

| Tolerance in thickness | DIN 16927 / ISO 11833-1 | mm | ± 0.15 | ± 0.15 | ± 0.15 |

| Horizontal flatness | DIN ISO 1101 | mm | 6 | 5 | 5 |

| Longitudinal roughness | DIN ISO 1101 | mm | 7 | 6 | 6 |

| Technical Properties | |||||

| Section Modulus W | DIN 53293 | cm3/m | 1.25 | 1.75 | 2.75 |

| Rigidity (Poisson's ratio μ = 0.3) E.J | DIN 53293 | kNm2/m | 0.14 | 0.28 | 0.63 |

| Alloy | EN 573-3 | ENAW | 1100 | ||

| Temper of Cover Sheets | EN 515 | H16/H18 | |||

| Modulus of Elasticity | EN 1999 1-1 | N/mm2 | 70,000 | ||

| Tensile Strength of Aluminium | EN 485-2 | N/mm2 | Rm ≥ 145 | ||

| 0.2% Proof Stress | EN 485-2 | N/mm2 | Rp0.2 ≥ 100 | ||

| Elongation | EN 485-2 | % | A50 ≥ 2 | ||

| Linear Thermal Expansion | EN 1999 1-1 | mm/m/℃ | 2.4 at 100℃ Temp difference | ||

| Core | |||||

| Polyethylene, Typ LD-PE | g/cm3 | 0.935 | |||

| Surface | Coil Coating | ||||

| Lacquering | Fluorocarbon based (PVdF) | ||||

| Thickness of coating | µm | two coating:≥26,three coating:≥32 | |||

| Gloss (initial value) | ECCA T2 | % | 30 - 80 | ||

| Pencil Hardness | ECCA T4 | H | |||

| Acoustical Properties | |||||

| Sound Absorption Factor άs | ISO 354 | 0.05 | |||

| Sound Transmission Loss RW | ISO 717-1 | DB | 25 | 26 | 28 |

| Loss Factor d | EN ISO 6721 | 0.0072 | 0.0087 | 0.0138 | |

| Thermal Properties | |||||

| Thermal Resistance R | DIN 52612 | m2K/W | 0.0069 | 0.0103 | 0.0172 |

| Heat Transition Coefficient U | DIN 4108 | W/m2K | 5.65 | 5.54 | 5.34 |

| Temperature Range | ℃ | -50…+80 | |||

| fire-protection rating | EN—13501 | ||||